Those of you who regularly read, or know me, know that we bought our current house in 2020. My wife and I plan to live in this house for at least ten years, so it makes sense that we would try and make it as comfortable and homey as possible.

That being said, we also recognize that it’s unlikely we will live in this house forever. When we first moved in, I realized the previous owner left behind (necessarily) a door on the linen closet in the master bathroom that served as a growth chart for their three sons and many of their grandchildren. What a shame, I thought, to leave these memories behind.*

As a result, I decided I was not going to make the same mistake. I was going to make my own growth chart to capture these family memories that we could take with us when we invariably move.

Planning and Requirements

To help with conceptualization, I took to the internet. There are lots available for purchase, and some especially beautiful ones by makers on Etsy. As I looked through, I took note of aspects I liked on some and disliked on others. One thing I know I didn’t like was charts that were simply painted slabs of wood. I much preferred ones that had carvings or something similar—there was just a greater sense of permanence to them that I found attractive.

But the price of some of these things… man. Totally reasonable prices for makers who do this professionally and are super talented. But… man.

I had planned on making the chart myself from the beginning, but was pleasantly surprised to find that it would end up saving me a fair bit of cash, too!

A few requirements I settled on for the design were:

- Tall enough to reasonably cover my little man’s growth potential (I’m six feet tall, so a little taller than that I’m hoping!).

- Short enough and narrow enough to fit on the inside of a doorway (under 80 inches tall and less than 4.5 inches wide).

- I liked the look of a ruler chart.

I picked up a seven-foot piece of oak one-by-four and got to work.

Making It!

I cut the seven-foot piece down to the height I decided upon: exactly 80 inches. Ambitious for someone whose parents are average height… I know. Then came measuring and penciling out all of the inch measurements on the wood, careful to use a speed square to ensure they were all perfectly perpendicular.

Once I had lines to work with, I got to work setting up my router with a V-groove bit to route out all of the inch increments. For each increment of one foot, I routed a deeper groove all the way across the wood piece. Each three- and six-inch sub-section, I routed slightly shallower and did not cross the entire piece. Finally, I routed the smallest, shallowest lines on the remaining inch measurements.

My last bit of router work was with a chamfer bit to cut around the outside of the entire work piece. I like to do this on a lot of woodworking I do because it removes sharp corners to give it a nice, finished appearance. You might recall I also chamfered the countertop edges I made in this post.

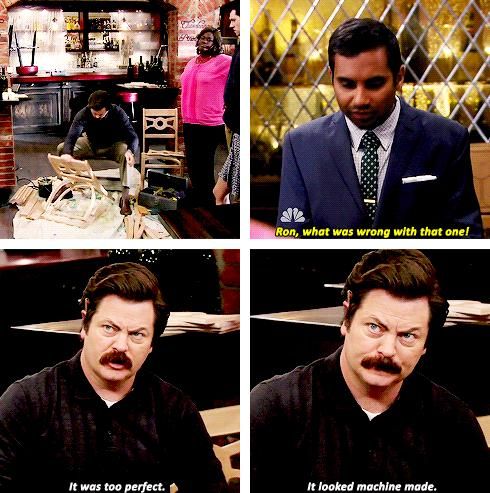

With the router put away, I took out my handy rotary tool and carved in numbers to mark off each one-foot segment. I did this freehand, so some came out better than others. Thankfully that just helps to make it look handmade, and I avoided the Ron Swanson trap of having to break it and start again because it was too perfect…

Then, it was on to itty bitty paintbrushes to paint the routed portions of the wood. Two coats later, I sanded down the entire piece, both front and back. I applied General Finishes Flat High Performance Polyurethane Interior Topcoat onto both the front and back of the piece.**

Sanded with a very high grit. Reapplied the finish once more.

Final Thoughts

Overall time spent on this project was probably close to four hours. I was pretty happy with how it turned out, and I was able to get it done in time for Little Man’s second birthday. There’s now a calendar reminder to take his height measurement every six months on his birthday and half birthday.

As we get further into renovating the house, maybe we’ll even come across a good spot to anchor the chart semi-permanently.

*When we renovate the bathroom, I plan on asking the family if they would like to have the door. I hate to see a piece of family history lost like that even if it’s not my family…

**Putting finish or paint on all sides of a piece of wood is actually helpful to prevent it from warping. This isn’t usually a problem if the wood was kiln-dried properly, but the difference in moisture levels within the piece of wood can still contribute to slight warping over time. For a piece like this, I wanted to ensure I did my best to keep it straight straight forever.e

Great project, and a terrific outcome.